CIESC Journal ›› 2019, Vol. 70 ›› Issue (8): 3086-3093.DOI: 10.11949/0438-1157.20190335

Previous Articles Next Articles

Runxia CAI1( ),Yiqun HUANG1,Lu CHENG1,Dongfang LI2,Chung-hwan JEON,Hairui YANG1,Junfu LYU1,Man ZHANG1(

),Yiqun HUANG1,Lu CHENG1,Dongfang LI2,Chung-hwan JEON,Hairui YANG1,Junfu LYU1,Man ZHANG1( )

)

Received:2019-04-02

Revised:2019-06-17

Online:2019-08-05

Published:2019-08-05

Contact:

Man ZHANG

蔡润夏1( ),黄逸群1,程璐1,李东方2,杨海瑞1,吕俊复1,张缦1(

),黄逸群1,程璐1,李东方2,杨海瑞1,吕俊复1,张缦1( )

)

通讯作者:

张缦

作者简介:蔡润夏(1991—),男,博士研究生,<email>cairx14@mails.tsinghua.edu.cn</email>

基金资助:CLC Number:

Runxia CAI, Yiqun HUANG, Lu CHENG, Dongfang LI, Chung-hwan JEON, Hairui YANG, Junfu LYU, Man ZHANG. Attrition of limestone during fluidized bed calcination and sulfation[J]. CIESC Journal, 2019, 70(8): 3086-3093.

蔡润夏, 黄逸群, 程璐, 李东方, 杨海瑞, 吕俊复, 张缦. 石灰石煅烧与硫化条件下磨耗特性[J]. 化工学报, 2019, 70(8): 3086-3093.

Add to citation manager EndNote|Ris|BibTeX

| 变量 | 参数 |

|---|---|

| 温度 /℃ | 800,850,900 |

| SO2浓度φ(SO2) /% | 0.1, 0.2 |

| 粒径(d 50/d 32)/μm | 346.2/320.4,609.7/586.4 |

| 反应条件 | 仅煅烧不硫化,先煅烧后硫化,同时煅烧和硫化 |

Table 1 Experimental parameters of attritions of limestone

| 变量 | 参数 |

|---|---|

| 温度 /℃ | 800,850,900 |

| SO2浓度φ(SO2) /% | 0.1, 0.2 |

| 粒径(d 50/d 32)/μm | 346.2/320.4,609.7/586.4 |

| 反应条件 | 仅煅烧不硫化,先煅烧后硫化,同时煅烧和硫化 |

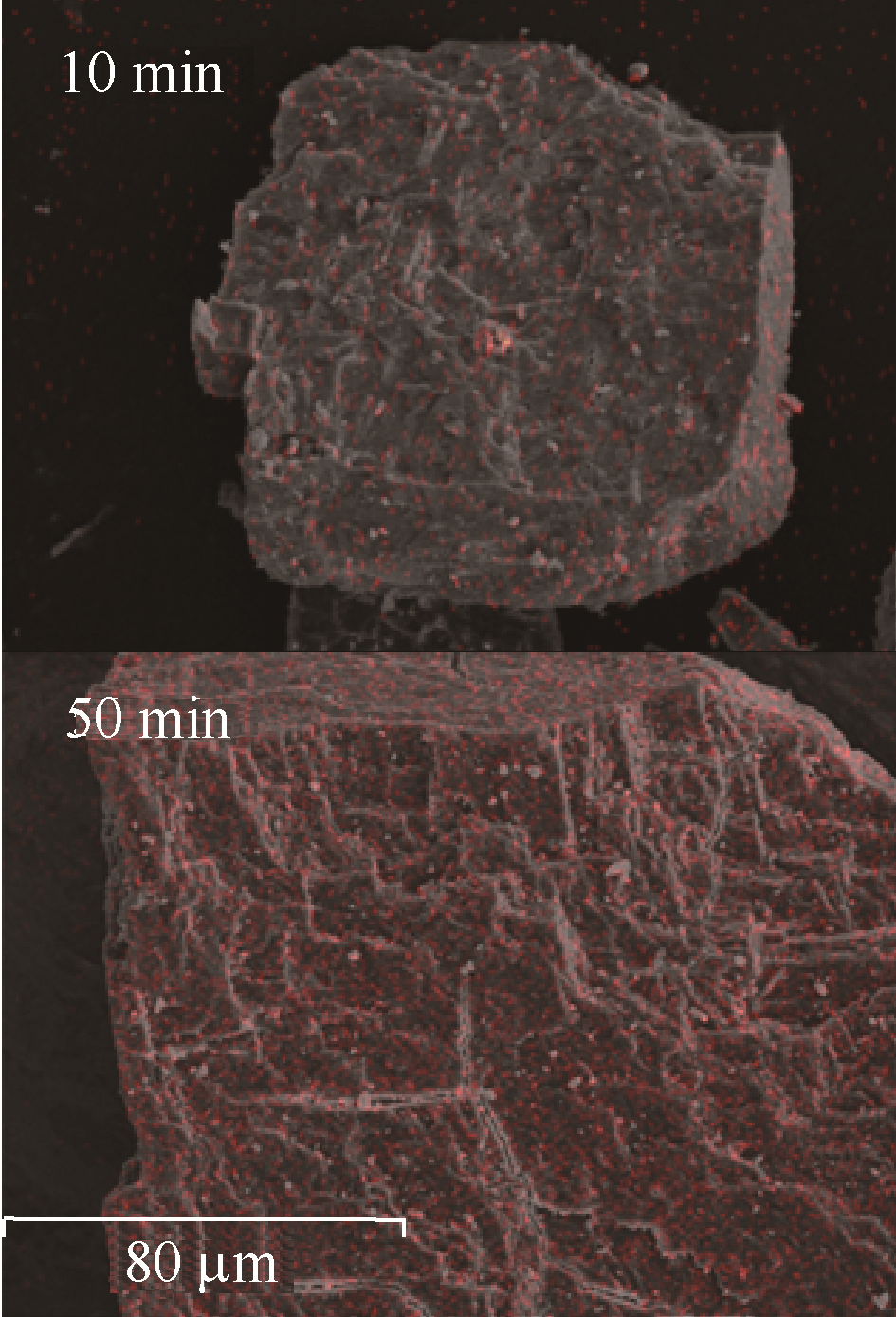

Fig.6 Energy spectrum analysis (EDS) of sulfur element of attrition particles at different time (simultaneous calcination and sulfation, 320 μm, φ(SO2)=0.2%)

| 1 | Anthony E J , Granatstein D L . Sulfation phenomena in fluidized bed combustion systems[J]. Progress in Energy and Combustion Science, 2001, 27(2): 215-236. |

| 2 | Cai R , Zhang H , Zhang M , et al . Development and application of the design principle of fluidization state specification in CFB coal combustion[J]. Fuel Processing Technology, 2018, 174: 41-52. |

| 3 | Lupiáñez C , Guedea I , Bolea I , et al . Experimental study of SO2 and NO x emissions in fluidized bed oxy-fuel combustion[J]. Fuel Processing Technology, 2013, 106: 587-594. |

| 4 | Lyngfelt A , Leckner B . Sulphur capture in circulating fluidized-bed boilers: can the efficiency be predicted?[J]. Chemical Engineering Science, 1999, 54(22): 5573-5584. |

| 5 | Hu N , Scaroni A W . Fragmentation of calcium-based sorbents under high heating rate, short residence time conditions[J]. Fuel, 1995, 74(3): 374-382. |

| 6 | Scala F , Salatino P . Dolomite attrition during fluidized-bed calcination and sulfation[J]. Combustion Science and Technology, 2003, 175(12): 2201-2216. |

| 7 | Di Benedetto A , Salatino P . Modelling attrition of limestone during calcination and sulfation in a fluidized bed reactor[J]. Powder Technology, 1998, 95(2): 119-128. |

| 8 | Saastamoinen J J , Shimizu T . Attrition-enhanced sulfur capture by limestone particles in fluidized beds[J]. Industrial & Engineering Chemistry Research, 2007, 46(4): 1079-1090. |

| 9 | 王进伟, 赵新木, 李少华,等 .循环流化床锅炉煤灰成分对其磨耗特性的影响[J]. 化工学报, 2007, 58(3): 739-744. |

| Wang J W , Zhao X M , Li S H , et al . Influence of coal ash components on attrition characteristics in circulating fluidized bed[J]. Journal of Chemical Industry and Engineering (China), 2007, 58(3): 739-744. | |

| 10 | Yang H , Yue G , Xiao X , et al . 1D modeling on the material balance in CFB boiler[J]. Chemical Engineering Science, 2005, 60(20): 5603-5611. |

| 11 | 崔健,段伦博,赵长遂 .混燃石油焦循环流化床锅炉硫污染物排放特性[J].化工学报, 2018, 69(5): 2158-2165. |

| Cui J , Duan L B , Zhao C S . Emission characteristics of sulfurous pollutant from circulating fluidized bed boilers co-firing petroleum coke and coal[J]. CIESC Journal, 2018, 69(5):2158-2165. | |

| 12 | 杨海瑞, Wirsum M , 吕俊复,等 . CFB锅炉内物料停留时间的模型研究[J]. 热能动力工程, 2003, 18(2): 143-146+214. |

| Yang H R , Wirsum M , Lyu J F , et al . Modeling research of residence time of materials in a circulating fluidized bed boiler [J]. Journal of Engineering for Thermal Energy and Power, 2003, 18(2): 143-146+214. | |

| 13 | Ar I , Balci S . Sulfation reaction between SO2 and limestone: application of deactivation model[J]. Chemical Engineering and Processing: Process Intensification, 2002, 41(2): 179-188. |

| 14 | Hartman M , Coughlin R W . Reaction of sulfur dioxide with limestone and the grain model[J]. AIChE Journal, 1976, 22(3):490-498. |

| 15 | Saastamoinen J , Pikkarainen T , Tourunen A , et al . Model of fragmentation of limestone particles during thermal shock and calcination in fluidised beds[J]. Powder Technology, 2008, 187(3): 244-251. |

| 16 | Saastamoinen J J . Particle-size optimization for SO2 capture by limestone in a circulating fluidized bed[J]. Industrial & Engineering Chemistry Research, 2007, 46(22): 7308-7316. |

| 17 | Scala F , Salatino P , Boerefijn R , et al . Attrition of sorbents during fluidized bed calcination and sulphation[J]. Powder Technology, 2000, 107(1/2): 153-167. |

| 18 | Scala F , Cammarota A , Chirone R , et al . Comminution of limestone during batch fluidized‐bed calcination and sulfation[J]. AIChE Journal, 1997, 43(2): 363-373. |

| 19 | Chirone R , Massimilla L , Salatino P . Comminution of carbons in fluidized bed combustion[J]. Progress in Energy and Combustion Science, 1991, 17(4): 297-326. |

| 20 | Montagnarn F , Salatino P , Scala F , et al . Sorbent inventory and particle size distribution in air-blown circulating fluidized bed combustors: the influence of particle attrition and fragmentation[C]//Proceedings of the 20th International Conference on Fluidized Bed Combustion. Berlin, Heidelberg: Springer, 2009: 966-971. |

| 21 | Scala F , Montagnaro F , Salatino P . Sulphation of limestones in a fluidized bed combustor: the relationship between particle attrition and microstructure[J]. The Canadian Journal of Chemical Engineering, 2008, 86(3): 347-355. |

| 22 | Yao X , Zhang H , Yang H , et al . An experimental study on the primary fragmentation and attrition of limestones in a fluidized bed[J]. Fuel Processing Technology, 2010, 91(9): 1119-1124. |

| 23 | Wang C , Chen L , Jia L , et al . Simultaneous calcination and sulfation of limestone in CFBB[J]. Applied Energy, 2015, 155: 478-484. |

| 24 | 王春波, 张斌, 陈亮,等 . 富氧燃烧气氛下石灰石煅烧/硫化特性及模型模拟[J]. 化工学报, 2015, 66(4): 1537-1543. |

| Wang C B , Zhang B , Chen L , et al . Characterization and modeling of limestone calcination and sulfation in oxy-fuel combustion atmosphere[J]. CIESC Journal, 2015, 66(4): 1537-1543. | |

| 25 | Borgwardt R H , Bruce K R , Blake J . An investigation of product-layer diffusivity for calcium oxide sulfation[J]. Industrial & Engineering Chemistry Research, 1987, 26(10): 1993-1998. |

| 26 | Wang C , Chen L . The effect of steam on simultaneous calcination and sulfation of limestone in CFBB[J]. Fuel, 2016, 175: 164-171. |

| 27 | Adánez J , Labiano F G , Abánades J C , et al . Methods for characterization of sorbents used in fluidized bed boilers[J]. Fuel, 1994, 73(3): 355-362. |

| 28 | de las Obras-Loscertales M , de Diego L F , García-Labiano F , et al . Modeling of limestone sulfation for typical oxy-fuel fluidized bed combustion conditions[J]. Energy & Fuels, 2013, 27(4): 2266-2274. |

| 29 | Mattisson T , Lyngfelt A . The reaction between limestone and SO2 under periodically changing oxidizing and reducing conditions— effect of temperature and limestone type[J]. Thermochimica Acta, 1999, 325(1): 59-67. |

| 30 | Kamarudin R A , Zakaria M S . The utilization of red gypsum waste for glazes[J]. The Malaysian Journal of Analytical Sciences, 2007, 11(1): 57-64. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||