化工学报 ›› 2019, Vol. 70 ›› Issue (5): 1750-1760.DOI: 10.11949/j.issn.0438-1157.20181470

收稿日期:2018-12-12

修回日期:2019-02-26

出版日期:2019-05-05

发布日期:2019-05-05

通讯作者:

赵蕾

作者简介:<named-content content-type="corresp-name">张爽</named-content>(1993—),男,硕士研究生,<email>944459447@qq.com</email>|赵蕾(1971—),女,博士,教授,<email>leizhao0308@hotmail.com</email>

基金资助:

Shuang ZHANG1( ),Lei ZHAO1(

),Lei ZHAO1( ),Lin GAO1,Hua LIU2

),Lin GAO1,Hua LIU2

Received:2018-12-12

Revised:2019-02-26

Online:2019-05-05

Published:2019-05-05

Contact:

Lei ZHAO

摘要:

桩基埋管换热器(能量桩)作为土壤源热泵的末端换热装置同时需承担常规桩基功能。因此,除其换热性能应满足空调供暖负荷需求之外,其间歇交替从周围土壤取、放热所引起的桩基应力变化亦不应危及上部建筑结构的稳定性。为了深刻揭示能量桩的热-力学特征,联合使用Comsol和Abaqus软件建立了并联双U形桩基埋管换热器的三维动态数值仿真模型,利用现场实测结果验证了仿真结果的正确性,分析了桩基内部的动态温度分布、轴力分布以及桩身位移状况;进一步探究了四种不同桩基长径比、流速情况下的双U形埋管以及三种不同埋管形式的桩基换热器的换热性能和力学特征,揭示了出口水温和单位桩深换热量等动态换热性能以及桩身轴力和桩顶位移等力学性能参数的时变特性。结果表明埋管形式和桩基长径比对桩基埋管换热器换热和力学性能的影响较显著,流速的影响较弱;长径比和流速越大,埋管的换热能力越大,但进、出口水温温差也越大,由温度变化所引起的附加桩身轴力、桩顶位移以及侧摩阻力也相应增大。

中图分类号:

张爽, 赵蕾, 高林, 刘华. 并联双U形桩基埋管换热器热-力学特征的数值仿真研究[J]. 化工学报, 2019, 70(5): 1750-1760.

Shuang ZHANG, Lei ZHAO, Lin GAO, Hua LIU. Exploration on thermo-mechanical characteristics of energy piles with double-U pipes buried in parallel by means of numerical simulations[J]. CIESC Journal, 2019, 70(5): 1750-1760.

图1 所模拟的桩基并联双U形埋管及其周围土壤计算域的几何尺寸

Fig.1 Geometry size of calculation domain of energy pile with double-U pipes buried in parallel pipe and surrounding soil simulated

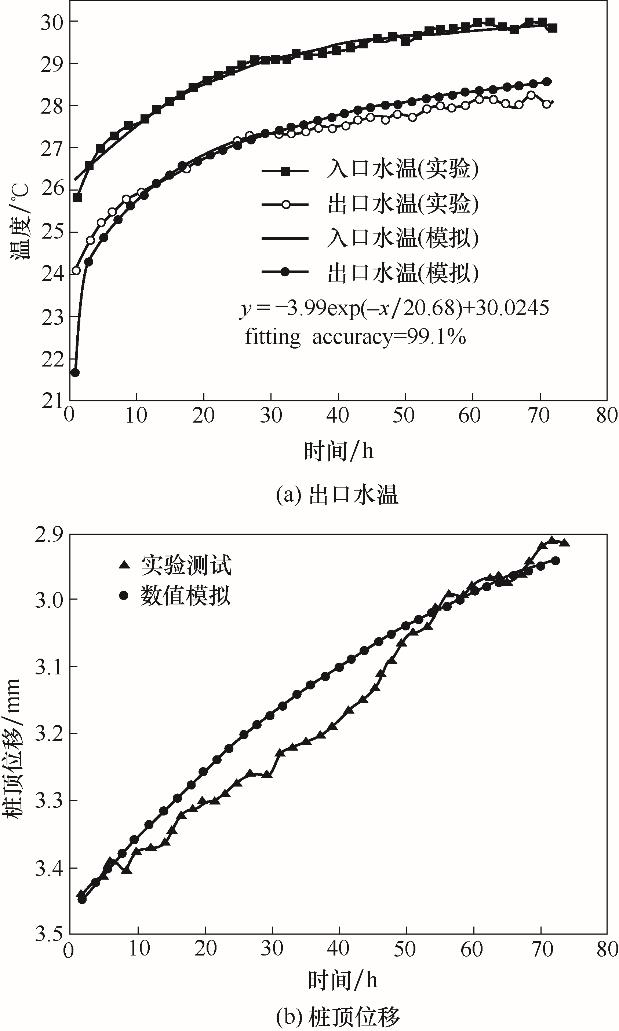

图3 72 h连续排热工况下的动态出口水温和桩顶位移实测值与模拟值对比

Fig.3 Comparison of measured and simulated outlet water temperatures and pile top displacements during 72 h continuous heat rejection process

| 参数 | 数值 |

|---|---|

| 桩基弹性模量E/GPa | 30 |

| 桩基热导率/(W· | 1.92 |

| 桩基热膨胀系数/℃-1 | 10-5 |

| 管壁热导率/(W· | 0.42 |

| 管壁比热容/(J· | 1465 |

| 土壤密度/(kg·m-3) | 1930 |

| 土壤弹性模量E/GPa | 0.015 |

| 土壤内摩擦角/(°) | 31 |

| 桩基泊松比 | 0.2 |

| 桩基密度/(kg·m-3) | 2500 |

| 桩基比热/(J· | 837 |

| 管壁密度/(kg·m-3) | 1100 |

| 土壤热导率/(W· | 1.87 |

| 土壤比热容/(J· | 1200 |

| 土壤泊松比 | 0.33 |

| 土壤膨胀角/(°) | 0 |

表1 工程现场实测相关参数

Table 1 Related parameters measured at project site

| 参数 | 数值 |

|---|---|

| 桩基弹性模量E/GPa | 30 |

| 桩基热导率/(W· | 1.92 |

| 桩基热膨胀系数/℃-1 | 10-5 |

| 管壁热导率/(W· | 0.42 |

| 管壁比热容/(J· | 1465 |

| 土壤密度/(kg·m-3) | 1930 |

| 土壤弹性模量E/GPa | 0.015 |

| 土壤内摩擦角/(°) | 31 |

| 桩基泊松比 | 0.2 |

| 桩基密度/(kg·m-3) | 2500 |

| 桩基比热/(J· | 837 |

| 管壁密度/(kg·m-3) | 1100 |

| 土壤热导率/(W· | 1.87 |

| 土壤比热容/(J· | 1200 |

| 土壤泊松比 | 0.33 |

| 土壤膨胀角/(°) | 0 |

图4 桩基各时刻沿径向温升曲线和第72小时不同深度处的径向温度场

Fig.4 Radial temperature rise of pile foundation at different time and radial temperature profiles at different depth at the 72th hour

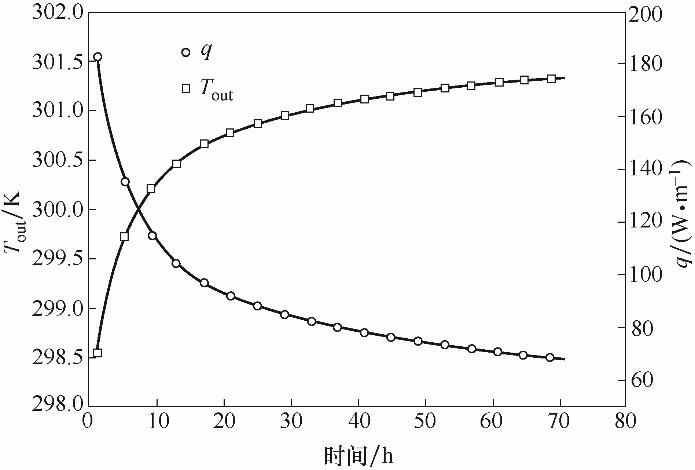

图6 连续排热72 h内双U形埋管出口水温及单位桩深换热量

Fig.6 Outlet water temperatures and heat exchange rates per pile depth of double-U pipes during continuous 72 h heat rejection process

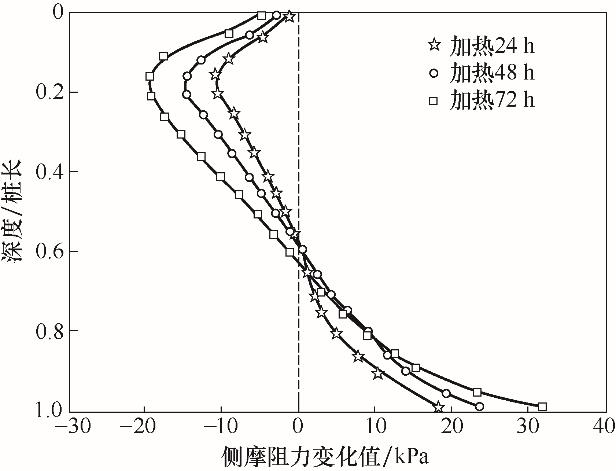

图9 温度变化引起双U形埋管桩基侧摩阻力变化值

Fig.9 Transient side frictional resistances along pile depth caused by temperature variations of pile with double-U pipes buried in parallel

图11 排热工况下(第72小时)不同流速时桩身轴力、桩身位移和桩侧摩阻力分布

Fig.11 Distribution of axial force, displacements of pile body and side frictional resistances along pile depth in cases of different flow rates in heat rejection mode at the 72th hour

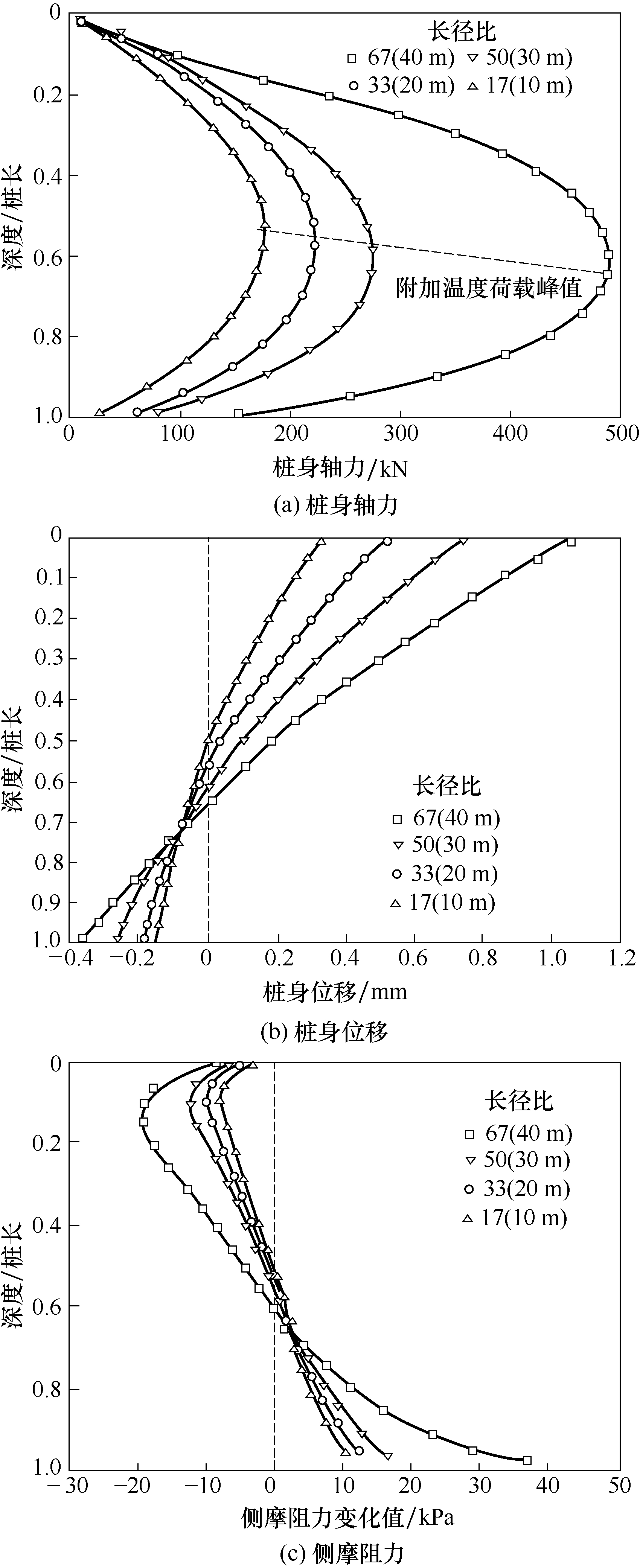

图13 排热工况下(第72小时)不同长径比时桩身轴力、桩身位移和桩侧摩阻力分布

Fig.13 Axial force of pile body, displacement of pile body and distribution of lateral friction of piles under different length to diameter ratios in heat removal mode at the 72th hour

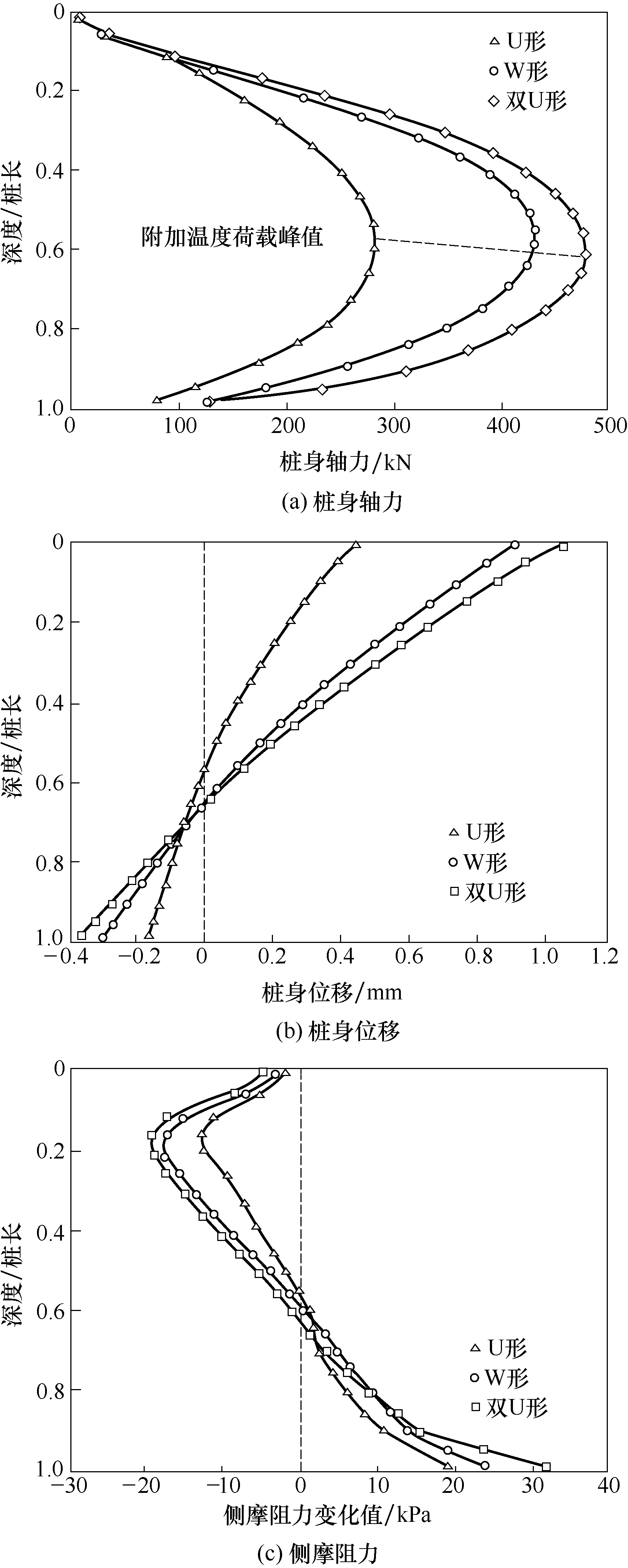

图15 排热模式下(第72小时)不同埋管形式情况下桩身轴力、桩身位移和桩侧摩阻力分布

Fig.15 Distribution of axial forces, pile displacements and lateral frictional resistances of piles with different forms of buried pipes operating in heat removal mode at the 72th hour

| 1 | Morino K , Oka T . Study on heat exchanged in soil by circylating water in a steel pile[J].Energy and Buildings, 1994, 21(1): 65-78. |

| 2 | Donna A D , Loria A F R , Laloui L . Numerical study of the response of a group of energy piles under different combinations of thermo-mechanical loads [J]. Computers & Geotechnics, 2016, 72: 126-142. |

| 3 | Murphy K D , Mccartney J S , Henry K S . Evaluation of thermo-mechanical and thermal behavior of full-scale energy foundations [J]. Acta Geotechnica, 2015, 10(2): 179-195. |

| 4 | Cecinato F , Loveridge F A . Influences on the thermal efficiency of energy piles[J]. Energy, 2015, 82: 1021-1033. |

| 5 | Zhao Q , Chen B , Liu F . Study on the thermal performance of several types of energy pile ground heat exchangers: U-shaped, W-shaped and spiral-shaped [J]. Energy & Buildings, 2016, 133: 335-344. |

| 6 | Park S , Lee D , Choi H J , et al . Relative constructability and thermal performance of cast-in-place concrete energy pile: coil-type GHEX (ground heat exchanger)[J]. Energy, 2015, 81: 56-66. |

| 7 | Zarrella A , Carli M D , Galgaro A . Thermal performance of two types of energy foundation pile: helical pipe and triple U-tube [J]. Applied Thermal Engineering, 2013, 61(2): 301-310. |

| 8 | Xin L I , Fang L , Fang Z H , et al . Coil heat source model for embedded spiral tube-based geothermal heat exchangers and its analytical solutions[J]. Journal of Engineering for Thermal Energy & Power, 2011, 26(4): 475-345. |

| 9 | Faizal M , Bouazza A , Rao M S . Heat transfer enhancement of geothermal energy piles [J]. Renewable & Sustainable Energy Reviews, 2016, 57: 16-33. |

| 10 | 赵海丰, 桂树强, 李强, 等 . 螺旋型埋管能源桩桩内温度场分布特征及其影响因素分析[J]. 长江科学院院报, 2017, 34(8): 153-158. |

| Zhao H F , Gui S Q , Li Q , et al . Analysis of temperature field distribution characteristics and influencing factors in spiral buried energy piles[J]. Journal of Yangtze River Scientific Research Institute, 2017, 34(8): 153-158. | |

| 11 | Eskilson P . Thermal analysis of heat extraction boreholes [D]. Lund, Sweden: Lund University, 1987. |

| 12 | Cui P , Li X , Man Y , et al . Heat transfer analysis of pile geothermal heat exchangers with spiral coils[J]. Apply Energy, 2011, 88(11): 4113-4119. |

| 13 | Selamat S , Miyara A , Kariya K . Numerical study of horizontal ground heat exchangers for design optimization[J].Renewable Energy, 2016, 95: 561-573. |

| 14 | Cane R L D , Forgas D A . Modeling of GSHP performance [J].ASHRAE Trans., 1991, 97(1): 909-925. |

| 15 | Dia N R , Cui P , Liu J H , et a1 . R&D of the ground-coupled heat pump technology in China[J]. Frontiers of Energy and Power Engineering in China, 2010, 4(1): 47-54. |

| 16 | Zhang W K , Yang H X , Lu L , et al . Investigation on heat transfer around buried coils of pile foundation heat exchangers for ground-coupled heat pump applications[J]. International Journal of Heat and Mass Transfer, 2012, 55(21/22): 6023-6031. |

| 17 | Wang C L , Liu H L , Kong G Q , et al . Different types of energy piles with heating–cooling cycles[J]. Geotechnical Engineering, 2017, 170(3): 1-12. |

| 18 | Gashti E H N , MalasKa M , Kujala K . Evaluation of thermo-mechanical behaviour of composite energy piles during heating/cooling operations [J]. Engineering Structures, 2014, 75(2): 363-373. |

| 19 | 赵强 . 螺旋埋管能量桩换热器的传热研究[D].济南: 山东大学, 2018. |

| Zhao Q . Study on heat transfer of spiral buried energy pile heat exchanger [D]. Jinan: Shandong University, 2018. | |

| 20 | 杨涛, 花永盛, 刘律智 . 悬浮能量桩热-力学基本特性的数值模拟[J]. 防灾减灾工程学报, 2017, (4): 518 - 524. |

| Yang T , Hua Y S , Liu L Z . Numerical simulation of the basic characteristics of thermal-mechanical properties of suspended energy piles[J]. Journal of Disaster Prevention and Mitigation Engineering, 2017, (4): 518-524. | |

| 21 | Brandl H . Energy foundations and thermo-active ground structures [J]. Geotechnique. 2006, 56(2): 81-122. |

| 22 | Yuan L C , Jie Z , Fan R M . Techno-economic evaluation of multiple energy piles for a ground-coupled heat pump system[J]. Energy Conversion and Management, 2018, 178: 200-216. |

| 23 | Lazaros A , Paul C , Georgios F . A review of the design aspects of ground heat exchangers[J]. Renewable and Sustainable Energy Reviews, 2018, 92: 753-773. |

| 24 | 黄旭, 孔纲强, 刘汉龙, 等 .不封底PCC能量桩与传统能量桩换热效率对比研究[J].防灾减灾工程学报, 2018, 38(5): 867-873. |

| Huang X , Kong G Q , Liu H L , et al . Comparative study on heat transfer efficiency between PCC energy piles and traditional energy piles without sealing [J]. Journal of Disaster Prevention and Mitigation Engineering, 2018, 38(5): 867-873. | |

| 25 | Laloui L , Moreni M , Vulliet L . Comportement d'un pieu bi-fonction, fondation et échangeur de chaleur[J]. Canadian Geotechnical Journal, 2003, 40(2): 388-402(15). |

| 26 | Bourne -Webb P G , Amatya B , Soga K , et al . Energy pile test at Lambeth College, London: geotechnical and thermodynamic aspects of pile response to heat cycles[J]. Geotechnique, 2009, 59(3): 237-248. |

| 27 | 桂树强, 程晓辉 .能源桩换热过程中结构响应原位试验研究[J].岩土工程学报, 2014, 36(6): 1087-1094. |

| Gui S Q , Cheng X H . In-situ experimental study on structural response of energy piles during heat transfer[J].Chinese Journal of Geotechnical Engineering, 2014, 36(6): 1087-1094. | |

| 28 | Go G H , Lee S R , Yoon S , et al . Design of spiral coil PHC energy pile considering effective borehole thermal resistance and groundwater advection effects [J]. Applied Energy, 2014, 125: 165-178. |

| 29 | 王成龙, 刘汉龙, 孔纲强, 等 . 不同埋管形式下能量桩热力学特性模型试验研究[J]. 工程力学, 2017, 34(1): 85-91. |

| Wang C L , Liu H L , Kong G Q , et al . Model test study on thermodynamic characteristics of energy piles under different buried pipes[J]. Engineering Mechanics, 2017, 34(1): 85-91. | |

| 30 | Batini N , Loria A F R , Conti P , et al . Energy and geotechnical behaviour of energy piles for different design solutions [J]. Applied Thermal Engineering, 2015, 86: 199-213. |

| [1] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [2] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [3] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [4] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [5] | 常明慧, 王林, 苑佳佳, 曹艺飞. 盐溶液蓄能型热泵循环特性研究[J]. 化工学报, 2023, 74(S1): 329-337. |

| [6] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [7] | 张化福, 童莉葛, 张振涛, 杨俊玲, 王立, 张俊浩. 机械蒸汽压缩蒸发技术研究现状与发展趋势[J]. 化工学报, 2023, 74(S1): 8-24. |

| [8] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [9] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [10] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [11] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [12] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [13] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [14] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [15] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号