化工学报 ›› 2021, Vol. 72 ›› Issue (6): 3359-3367.DOI: 10.11949/0438-1157.20201476

吴贵豪1,3( ),朱有健2,3(

),朱有健2,3( ),樊纪原3,成伟3,蒋好3,杨海平3,陈汉平3(

),樊纪原3,成伟3,蒋好3,杨海平3,陈汉平3( )

)

收稿日期:2020-10-22

修回日期:2021-01-17

出版日期:2021-06-05

发布日期:2021-06-05

通讯作者:

朱有健,陈汉平

作者简介:吴贵豪(1995—),男,硕士研究生,基金资助:

WU Guihao1,3( ),ZHU Youjian2,3(

),ZHU Youjian2,3( ),FAN Jiyuan3,CHENG Wei3,JIANG Hao3,YANG Haiping3,CHEN Hanping3(

),FAN Jiyuan3,CHENG Wei3,JIANG Hao3,YANG Haiping3,CHEN Hanping3( )

)

Received:2020-10-22

Revised:2021-01-17

Online:2021-06-05

Published:2021-06-05

Contact:

ZHU Youjian,CHEN Hanping

摘要:

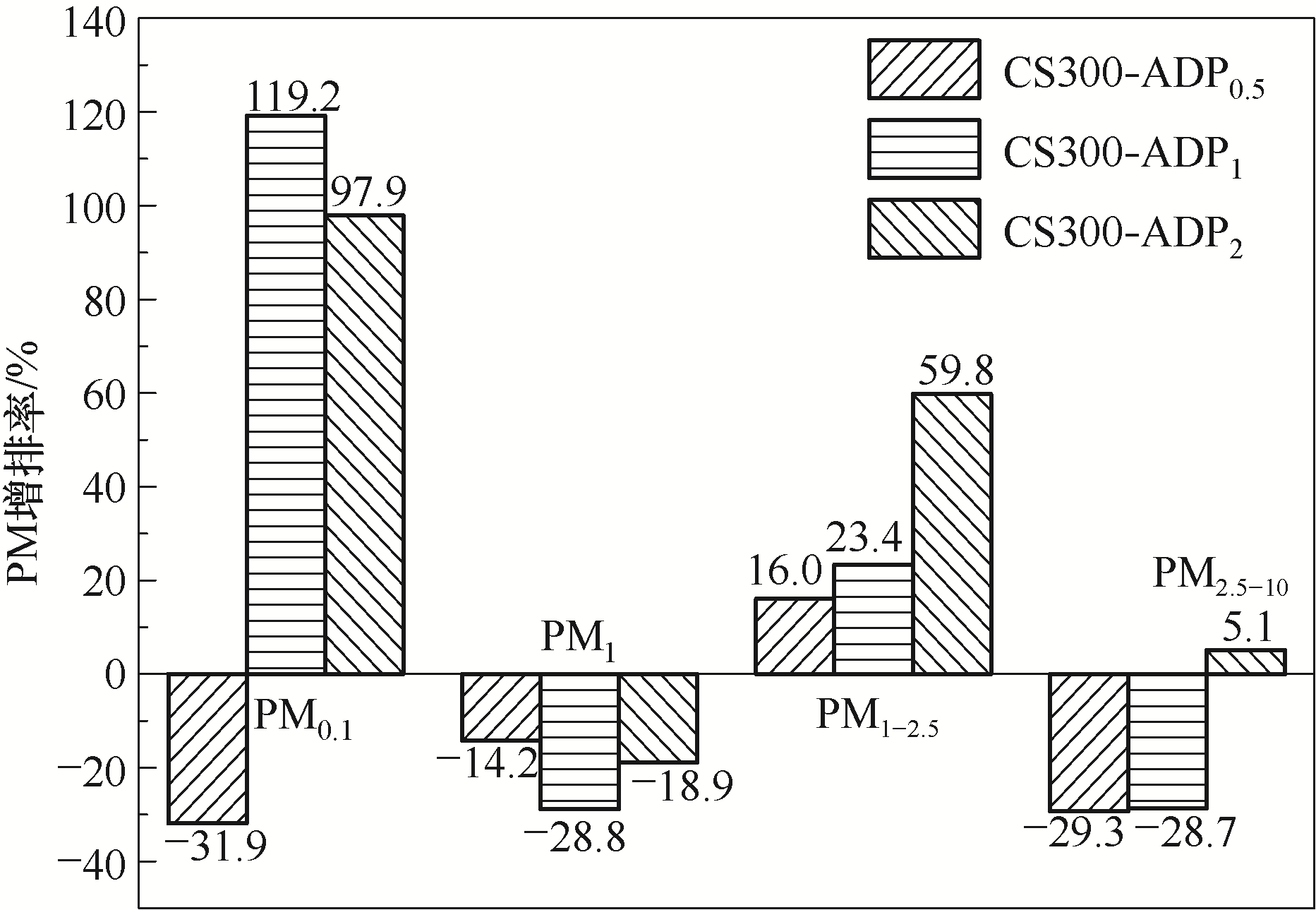

使用立式管式炉反应器并结合低压撞击器颗粒物采集装置研究了玉米秆掺混磷酸二氢铵(NH4H2PO4)烘焙对烘焙产物理化性质及固定床中燃烧颗粒物排放的影响。结果表明,玉米秆单独烘焙可有效提升生物质品质,但也提升了颗粒物排放。300℃烘焙时,PM1、PM1-2.5和PM2.5-10分别增排76.5%、194.8%和170.2%。在烘焙过程掺混NH4H2PO4可进一步提质,使得固体产物灰分有不同程度的增加,显著降低固体产物的O/C比,并提高样品的无灰基热值。此外,研究发现掺混NH4H2PO4可显著提高烘焙过程Cl的释放率并降低固体产物中Cl的含量,有利于降低后续燃烧PM1的排放。在掺混比例P/K摩尔比为1时减排效果最佳,此时PM1相比无掺混时减排28.8%。结果表明在生物质烘焙过程引入NH4H2PO4可以促进Cl的脱除并减少后续燃烧过程细颗粒物的排放,是一种有前景的生物质预处理手段。

中图分类号:

吴贵豪, 朱有健, 樊纪原, 成伟, 蒋好, 杨海平, 陈汉平. 磷酸二氢铵对玉米秆烘焙及固定床燃烧颗粒物排放特性的影响[J]. 化工学报, 2021, 72(6): 3359-3367.

WU Guihao, ZHU Youjian, FAN Jiyuan, CHENG Wei, JIANG Hao, YANG Haiping, CHEN Hanping. Effects of the addition of NH4H2PO4 in corn stalk on torrefaction and PM emissions in fixed bed combustion[J]. CIESC Journal, 2021, 72(6): 3359-3367.

| 样品 | 工业分析/%(质量) | 元素分析/%(质量) | 原子比 | HHV/(MJ/kg) | HHV①/(MJ/kg) | 固碳率/% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ash | Volatile | Fixed carbon | C | H | O② | N | S | O/C | H/C | ||||

| CS | 8.69 | 73.87 | 17.44 | 43.06 | 5.72 | 41.27 | 0.74 | 0.52 | 0.96 | 0.13 | 16.16 | 17.70 | 100.00 |

| CS220 | 9.47 | 71.53 | 19.00 | 45.76 | 5.69 | 37.62 | 1.05 | 0.41 | 0.82 | 0.12 | 17.77 | 19.63 | 98.85 |

| CS220-ADP0.5 | 10.69 | 68.64 | 20.67 | 45.75 | 5.41 | 36.86 | 1.03 | 0.25 | 0.81 | 0.12 | 17.53 | 19.73 | 93.09 |

| CS220-ADP1 | 13.27 | 66.79 | 19.94 | 45.90 | 5.36 | 33.92 | 1.29 | 0.25 | 0.74 | 0.12 | 17.29 | 19.91 | 90.28 |

| CS220-ADP2 | 20.36 | 58.42 | 21.23 | 45.70 | 5.04 | 27.09 | 1.67 | 0.14 | 0.59 | 0.11 | 16.79 | 21.42 | 84.36 |

| CS260 | 10.55 | 62.59 | 26.86 | 46.78 | 5.33 | 35.90 | 1.09 | 0.36 | 0.77 | 0.11 | 18.41 | 20.58 | 86.07 |

| CS260-ADP0.5 | 11.40 | 63.00 | 25.60 | 46.91 | 5.19 | 35.06 | 1.24 | 0.21 | 0.75 | 0.11 | 18.14 | 20.39 | 83.46 |

| CS260-ADP1 | 15.60 | 61.31 | 23.08 | 46.92 | 5.06 | 30.80 | 1.44 | 0.19 | 0.66 | 0.11 | 17.87 | 20.91 | 82.04 |

| CS260-ADP2 | 16.41 | 57.87 | 25.72 | 47.47 | 4.86 | 29.51 | 1.65 | 0.10 | 0.62 | 0.10 | 17.31 | 23.25 | 80.00 |

| CS300 | 11.29 | 45.45 | 43.26 | 55.55 | 4.55 | 26.78 | 1.41 | 0.41 | 0.48 | 0.08 | 20.11 | 22.67 | 63.99 |

| CS300-ADP0.5 | 14.24 | 49.31 | 36.45 | 52.91 | 4.52 | 26.64 | 1.51 | 0.19 | 0.50 | 0.09 | 19.72 | 22.96 | 60.95 |

| CS300-ADP1 | 19.36 | 46.99 | 33.65 | 52.91 | 4.37 | 21.56 | 1.63 | 0.18 | 0.41 | 0.08 | 19.38 | 23.89 | 64.64 |

| CS300-ADP2 | 30.05 | 39.71 | 30.25 | 54.16 | 3.86 | 9.46 | 2.38 | 0.09 | 0.17 | 0.07 | 18.68 | 27.00 | 67.90 |

表1 实验样品理化性质(干燥基)

Table 1 Physical and chemical properties of experimental samples(dry basis)

| 样品 | 工业分析/%(质量) | 元素分析/%(质量) | 原子比 | HHV/(MJ/kg) | HHV①/(MJ/kg) | 固碳率/% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ash | Volatile | Fixed carbon | C | H | O② | N | S | O/C | H/C | ||||

| CS | 8.69 | 73.87 | 17.44 | 43.06 | 5.72 | 41.27 | 0.74 | 0.52 | 0.96 | 0.13 | 16.16 | 17.70 | 100.00 |

| CS220 | 9.47 | 71.53 | 19.00 | 45.76 | 5.69 | 37.62 | 1.05 | 0.41 | 0.82 | 0.12 | 17.77 | 19.63 | 98.85 |

| CS220-ADP0.5 | 10.69 | 68.64 | 20.67 | 45.75 | 5.41 | 36.86 | 1.03 | 0.25 | 0.81 | 0.12 | 17.53 | 19.73 | 93.09 |

| CS220-ADP1 | 13.27 | 66.79 | 19.94 | 45.90 | 5.36 | 33.92 | 1.29 | 0.25 | 0.74 | 0.12 | 17.29 | 19.91 | 90.28 |

| CS220-ADP2 | 20.36 | 58.42 | 21.23 | 45.70 | 5.04 | 27.09 | 1.67 | 0.14 | 0.59 | 0.11 | 16.79 | 21.42 | 84.36 |

| CS260 | 10.55 | 62.59 | 26.86 | 46.78 | 5.33 | 35.90 | 1.09 | 0.36 | 0.77 | 0.11 | 18.41 | 20.58 | 86.07 |

| CS260-ADP0.5 | 11.40 | 63.00 | 25.60 | 46.91 | 5.19 | 35.06 | 1.24 | 0.21 | 0.75 | 0.11 | 18.14 | 20.39 | 83.46 |

| CS260-ADP1 | 15.60 | 61.31 | 23.08 | 46.92 | 5.06 | 30.80 | 1.44 | 0.19 | 0.66 | 0.11 | 17.87 | 20.91 | 82.04 |

| CS260-ADP2 | 16.41 | 57.87 | 25.72 | 47.47 | 4.86 | 29.51 | 1.65 | 0.10 | 0.62 | 0.10 | 17.31 | 23.25 | 80.00 |

| CS300 | 11.29 | 45.45 | 43.26 | 55.55 | 4.55 | 26.78 | 1.41 | 0.41 | 0.48 | 0.08 | 20.11 | 22.67 | 63.99 |

| CS300-ADP0.5 | 14.24 | 49.31 | 36.45 | 52.91 | 4.52 | 26.64 | 1.51 | 0.19 | 0.50 | 0.09 | 19.72 | 22.96 | 60.95 |

| CS300-ADP1 | 19.36 | 46.99 | 33.65 | 52.91 | 4.37 | 21.56 | 1.63 | 0.18 | 0.41 | 0.08 | 19.38 | 23.89 | 64.64 |

| CS300-ADP2 | 30.05 | 39.71 | 30.25 | 54.16 | 3.86 | 9.46 | 2.38 | 0.09 | 0.17 | 0.07 | 18.68 | 27.00 | 67.90 |

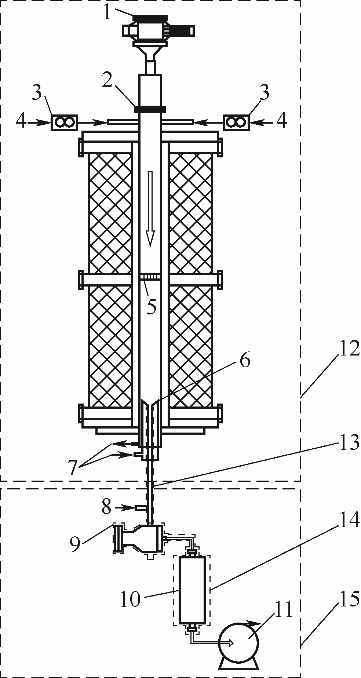

图1 固定床燃烧装置图1—压电式给料机;2—不锈钢反应器;3—质量流量计;4—空气;5—不锈钢多孔挡板;6—采样探头;7—水冷系统;8—稀释气体;9—旋风除尘器;10—低压冲击采样装置;11—真空泵;12—燃料燃烧系统;13—PM采样点;14—电加热带;15—PM样品采集系统

Fig.1 Fixed bed combustion schematic

| 样品 | Yield/(mg/g fuel) | (PM1 / PM10)/% | ||||||

|---|---|---|---|---|---|---|---|---|

| PM0.1 | PM0.1-1 | PM1 | PM1-2.5 | PM2.5 | PM2.5-10 | PM10 | ||

| CS | 0.466±0.096 | 7.511±0.302 | 7.977±0.347 | 1.122±0.078 | 9.099±0.426 | 0.939±0.046 | 10.038±0.473 | 79.47 |

| CS220 | 0.252±0.095 | 9.334±0.184 | 9.586±0.278 | 1.332±0.052 | 10.918±0.332 | 1.027±0.018 | 11.945±0.313 | 80.25 |

| CS260 | 0.199±0.027 | 10.277±0.259 | 10.476±0.545 | 1.814±0.323 | 12.290±0.221 | 1.274±0.109 | 13.564±0.111 | 77.23 |

| CS300 | 0.338±0.087 | 13.743±0.393 | 14.081±0.481 | 3.309±0.170 | 17.390±0.310 | 2.536±0.070 | 19.926±0.239 | 70.67 |

表2 燃烧过程中玉米秆及其烘焙样各粒径区间颗粒物的产量及PM1在PM10中的占比

Table 2 The yield of PM in each size range and the proportion of PM1 in PM10 during combustion of torrefied corn stalk

| 样品 | Yield/(mg/g fuel) | (PM1 / PM10)/% | ||||||

|---|---|---|---|---|---|---|---|---|

| PM0.1 | PM0.1-1 | PM1 | PM1-2.5 | PM2.5 | PM2.5-10 | PM10 | ||

| CS | 0.466±0.096 | 7.511±0.302 | 7.977±0.347 | 1.122±0.078 | 9.099±0.426 | 0.939±0.046 | 10.038±0.473 | 79.47 |

| CS220 | 0.252±0.095 | 9.334±0.184 | 9.586±0.278 | 1.332±0.052 | 10.918±0.332 | 1.027±0.018 | 11.945±0.313 | 80.25 |

| CS260 | 0.199±0.027 | 10.277±0.259 | 10.476±0.545 | 1.814±0.323 | 12.290±0.221 | 1.274±0.109 | 13.564±0.111 | 77.23 |

| CS300 | 0.338±0.087 | 13.743±0.393 | 14.081±0.481 | 3.309±0.170 | 17.390±0.310 | 2.536±0.070 | 19.926±0.239 | 70.67 |

图7 玉米秆掺混不同比例ADP烘焙后燃烧过程中PM0.1、PM1、PM1-2.5及PM2.5-10的增排率

Fig.7 Increase rate of PM0.1, PM1, PM1-2.5 and PM2.5-10 from torrefied corn stalk with ADP during combustion

| 样品 | Yield/(mg/g fuel) | (PM1 / PM10)/% | ||||||

|---|---|---|---|---|---|---|---|---|

| PM0.1 | PM0.1-1 | PM1 | PM1-2.5 | PM2.5 | PM2.5-10 | PM10 | ||

| CS300 | 0.338±0.087 | 13.743±0.393 | 14.081±0.481 | 3.309±0.170 | 17.390±0.310 | 2.536±0.070 | 19.926±0.239 | 70.67 |

| CS300-ADP0.5 | 0.230±0.044 | 11.857±0.193 | 12.087±0.148 | 3.840±0.001 | 15.927±0.146 | 1.794±0.033 | 17.721±0.112 | 68.21 |

| CS300-ADP1 | 0.741±0.245 | 9.282±0.713 | 10.023±0.959 | 4.083±0.319 | 14.105±0.639 | 1.809±0.156 | 15.914±0.483 | 62.98 |

| CS300-ADP2 | 0.669±0.168 | 10.756±0.228 | 11.425±0.397 | 5.286±0.232 | 16.711±0.630 | 2.665±0.006 | 19.377±0.637 | 58.96 |

表3 玉米秆掺混不同比例ADP的300℃烘焙样燃烧过程中各粒径区间颗粒物的产量及PM1在PM10中的占比

Table 3 The yield of PM in each size range and the proportion of PM1 in PM10 during combustion of torrefied sample

| 样品 | Yield/(mg/g fuel) | (PM1 / PM10)/% | ||||||

|---|---|---|---|---|---|---|---|---|

| PM0.1 | PM0.1-1 | PM1 | PM1-2.5 | PM2.5 | PM2.5-10 | PM10 | ||

| CS300 | 0.338±0.087 | 13.743±0.393 | 14.081±0.481 | 3.309±0.170 | 17.390±0.310 | 2.536±0.070 | 19.926±0.239 | 70.67 |

| CS300-ADP0.5 | 0.230±0.044 | 11.857±0.193 | 12.087±0.148 | 3.840±0.001 | 15.927±0.146 | 1.794±0.033 | 17.721±0.112 | 68.21 |

| CS300-ADP1 | 0.741±0.245 | 9.282±0.713 | 10.023±0.959 | 4.083±0.319 | 14.105±0.639 | 1.809±0.156 | 15.914±0.483 | 62.98 |

| CS300-ADP2 | 0.669±0.168 | 10.756±0.228 | 11.425±0.397 | 5.286±0.232 | 16.711±0.630 | 2.665±0.006 | 19.377±0.637 | 58.96 |

| 1 | Barskov S, Zappi M, Buchireddy P, et al. Torrefaction of biomass: a review of production methods for biocoal from cultured and waste lignocellulosic feedstocks[J]. Renewable Energy, 2019, 142: 624-642. |

| 2 | Ong H C, Chen W, Singh Y, et al. A state-of-the-art review on thermochemical conversion of biomass for biofuel production: a TG-FTIR approach[J]. Energy Conversion and Management, 2020, 209: 112634. |

| 3 | Chen Z, Wang M, Jiang E, et al. Pyrolysis of torrefied biomass[J]. Trends in Biotechnology, 2018, 36(12): 1287-1298. |

| 4 | Hernández J J, Lapuerta M, Monedero E, et al. Biomass quality control in power plants: technical and economical implications[J]. Renewable Energy, 2018, 115: 908-916. |

| 5 | Niu Y, Lv Y, Lei Y, et al. Biomass torrefaction: properties, applications, challenges, and economy[J]. Renewable and Sustainable Energy Reviews, 2019, 115: 109395. |

| 6 | Xin S, Mi T, Liu X, et al. Effect of torrefaction on the pyrolysis characteristics of high moisture herbaceous residues[J]. Energy, 2018, 152: 586-593. |

| 7 | Wang L, Barta-Rajnai E, Skreiberg Ø, et al. Effect of torrefaction on physiochemical characteristics and grindability of stem wood, stump and bark[J]. Applied Energy, 2018, 227: 137-148. |

| 8 | van Lith S C, Jensen P A, Frandsen F J, et al. Release to the gas phase of inorganic elements during wood combustion (Part 2): Influence of fuel composition[J]. Energy & Fuels, 2008, 22(3): 1598-1609. |

| 9 | Johansen J M, Jakobsen J G, Frandsen F J, et al. Release of K, Cl, and S during pyrolysis and combustion of high-chlorine biomass[J]. Energy & Fuels, 2011, 25(11): 4961-4971. |

| 10 | Saleh S B, Flensborg J P, Shoulaifar T K, et al. Release of chlorine and sulfur during biomass torrefaction and pyrolysis[J]. Energy & Fuels, 2014, 28(6): 3738-3746. |

| 11 | Chen D, Gao A, Ma Z, et al. In-depth study of rice husk torrefaction: characterization of solid, liquid and gaseous products, oxygen migration and energy yield[J]. Bioresource Technology, 2018, 253: 148-153. |

| 12 | Yani S, Gao X, Wu H. Emission of Inorganic PM10 from the combustion of torrefied biomass under pulverized-fuel conditions[J]. Energy & Fuels, 2015, 29(2): 800-807. |

| 13 | Hu Z, Wang X, Adeosun A, et al. Aggravated fine particulate matter emissions from heating-upgraded biomass and biochar combustion: the effect of pretreatment temperature[J]. Fuel Processing Technology, 2018, 171: 1-9. |

| 14 | Kai X, Meng Y, Yang T, et al. Effect of torrefaction on rice straw physicochemical characteristics and particulate matter emission behavior during combustion[J]. Bioresource Technology, 2019, 278: 1-8. |

| 15 | Xu Y, Liu X, Zhang Y, et al. A novel Ti-based sorbent for reducing ultrafine particulate matter formation during coal combustion[J]. Fuel, 2017, 193: 72-80. |

| 16 | Si J, Liu X, Xu M, et al. Effect of kaolin additive on PM2.5 reduction during pulverized coal combustion: Importance of sodium and its occurrence in coal[J]. Applied Energy, 2014, 114: 434-444. |

| 17 | Yang W, Zhu Y, Cheng W, et al. Effect of minerals and binders on particulate matter emission from biomass pellets combustion[J]. Applied Energy, 2018, 215: 106-115. |

| 18 | 樊纪原, 朱有健, 吴贵豪, 等. 磷酸二氢铵对生物质燃烧过程中颗粒物排放特性的影响[J]. 中国电机工程学报, 2020, 40(1): 176-182. |

| Fan J Y, Zhu Y J, Wu G H, et al. Effect of NH4H2PO4 additives on PM emissions from the combustion of biomass [J]. Proceedings of the Chinese Society of Electrical Engineering, 2020, 40(1): 176-182. | |

| 19 | Liu X R, Yuan L J, Yang X D. Evolution of chemical functional groups during torrefaction of rice straw[J]. Bioresource Technology, 2021, 320: 124328. |

| 20 | Shao J A, Cheng W, Zhu Y, et al. Effects of combined torrefaction and pelletization on particulate matter emission from biomass pellet combustion[J]. Energy & Fuels, 2019, 33(9): 8777-8785. |

| 21 | 刘恒. 烘焙对玉米秆Cl、S及AAEMs迁徙转化特性影响的研究[D]. 武汉: 华中科技大学, 2019 |

| Liu H. Effects of torrefaction on migration and transformation characteristics of Cl, S and AAEMs in corn stalks [D]. Wuhan: Huazhong University of Science and Technology, 2019. | |

| 22 | Zhao L, Cao X, Zheng W, et al. Copyrolysis of biomass with phosphate fertilizers to improve biochar carbon retention, slow nutrient release, and stabilize heavy metals in soil[J]. ACS Sustainable Chemistry & Engineering, 2016, 4(3): 1630-1636. |

| 23 | 赵乘寿, 宫聪, 汪鹏, 等.含磷酸二氢铵细水雾灭火有效性研究[J].消防科学与技术, 2011, 30(9): 822-824. |

| Zhao C S, Gong C, Wang P, et al. Experimental study on fire suppression effectiveness of water mist with ammonium dihydrogen phosphate[J]. Fire Science and Technology, 2011, 30(9): 822-824. | |

| 24 | 贡长生. 现代磷化工技术和应用[M]. 北京: 化学工业出版社, 2013: 843-860. |

| Gong C S. Modern Phosphorus Chemical Technology and Application[M]. Beijing: Chemical Industry Press, 2013: 843-860. | |

| 25 | Wang Q, Han K, Gao J, et al. Investigation of maize straw char briquette ash fusion characteristics and the influence of phosphorus additives[J]. Energy & Fuels, 2017, 31(3): 2822-2830. |

| 26 | Zhu Y, Fan J, Yang P, et al. P-based additive for reducing fine particulate matter emissions during agricultural biomass combustion[J]. Energy & Fuels, 2019, 33(11): 11274-11284. |

| 27 | 赵京, 张玉锋, 魏小林, 等. 高碱煤燃烧过程中亚微米颗粒物PM1的生成特性[J]. 化工学报, 2019, 70(8): 3113-3120. |

| Zhao J, Zhang Y F, Wei X L, et al. PM1 formation characteristics during high-alkali coal combustion [J]. CIESC Journal, 2019, 70(8): 3113-3120. | |

| 28 | 郑传杰, 盛昌栋. 高温烟气中吸附剂捕集K的模型及其反应动力学研究[J]. 化工学报, 2019, 70(6): 2259-2268. |

| Zheng C J, Sheng C D. Modeling and reaction kinetics study on K capture by adsorbents in high temperature flue gas [J]. CIESC Journal, 2019, 70(6): 2259-2268. | |

| 29 | 于敦喜, 徐明厚, 易帆, 等. 燃煤过程中颗粒物的形成机理研究进展[J]. 煤炭转化, 2004, (4): 7-12. |

| Yu D X, Xu M H, Yi F, et al. A review on particle formation mechanisms during coal combustion [J]. Coal Conversion, 2004, (4): 7-12. | |

| 30 | 孔卉茹, 张媛媛, 李永茂, 等. 低热值煤电厂配煤技术研究进展[J]. 洁净煤技术, 2016, 22(6): 1-9. |

| Kong H R, Zhang Y Y, Li Y M, et al. Development tendency of coal blending technologies in coal-fired power plants burning low calorific value coal [J]. Clean Coal Technology, 2016, 22(6): 1-9. | |

| 31 | Novaković A, van Lith S C, Frandsen F J, et al. Release of potassium from the systems K-Ca-Si and K-Ca-P[J]. Energy & Fuels, 2009, 23(7): 3423-3428. |

| [1] | 郑玉圆, 葛志伟, 韩翔宇, 王亮, 陈海生. 中高温钙基材料热化学储热的研究进展与展望[J]. 化工学报, 2023, 74(8): 3171-3192. |

| [2] | 时国华, 何林珅, 赵玺灵, 张世钢. 余热回收喷淋塔的烟气颗粒物脱除特性研究[J]. 化工学报, 2023, 74(4): 1735-1745. |

| [3] | 陈俊先, 姬忠礼, 赵瑜, 张倩, 周岩, 刘猛, 刘震. 基于微波技术的天然气管道内颗粒物在线检测方法研究[J]. 化工学报, 2023, 74(3): 1042-1053. |

| [4] | 王绍壮, 于敦喜, 李佳忆, 韩京昆, 喻鑫, 刘芳琪. 烟气烘焙对玉米秆可磨性的影响规律研究[J]. 化工学报, 2023, 74(2): 861-870. |

| [5] | 卢道铭, 唐钊艇, 范怡平, 卢春喜. 大差异颗粒分级再生设备的性能研究[J]. 化工学报, 2021, 72(8): 4184-4195. |

| [6] | 熊桂龙, 谢静雯, 杨林军. 粗糙度对水汽在细颗粒表面异质核化影响的数值模拟[J]. 化工学报, 2021, 72(8): 4304-4313. |

| [7] | 侯勇俊, 祝敬涛, 李华川, 吴先进, 蒋锐. 均衡运动旋转振动筛DEM数值模拟[J]. 化工学报, 2021, 72(5): 2706-2717. |

| [8] | 余作伟, 刘倩, 钟文琪, 周骏. 烘焙生物质燃烧过程中钾的赋存形态及析出迁移特性[J]. 化工学报, 2021, 72(4): 2258-2266. |

| [9] | 马润梅, 赵祥, 李双喜, 刘兴华, 许灿. 颗粒介质用机械密封热力耦合变形及摩擦磨损研究[J]. 化工学报, 2021, 72(11): 5726-5737. |

| [10] | 朱有健, 张显显, 陈奕名, 吴学红, 杨海平, 陈汉平. 磷酸二氢钙对玉米秆灰熔融烧结特性的影响研究[J]. 化工学报, 2020, 71(7): 3313-3321. |

| [11] | 余廷芳, 高巨, 熊桂龙, 李水清, 姚强. 基于分子运动学的水汽在细颗粒表面异质核化的数值模拟[J]. 化工学报, 2020, 71(7): 3071-3079. |

| [12] | 詹飞龙, 丁国良, 庄大伟, 张浩, 武滔, 叶向阳. 析湿工况下翅片管式换热器表面粉尘沉积过程的数值模型[J]. 化工学报, 2020, 71(5): 1986-1994. |

| [13] | 李英泽, 杨路, 王琦, 杨思宇. BGL炉煤气化过程建模和模拟[J]. 化工学报, 2020, 71(3): 1174-1188. |

| [14] | 蒋好,朱有健,刘恒,邵敬爱,成伟,杨鹏,吴贵豪,杨海平,陈汉平. 秸秆烘焙过程氯、硫释放及AAEMs迁徙转化特性研究[J]. 化工学报, 2020, 71(12): 5785-5792. |

| [15] | 辛善志, 黄芳, 刘晓烨, 许庆利, 米铁. 烘焙中药渣的热解与燃烧特性及其动力学分析[J]. 化工学报, 2019, 70(8): 3142-3150. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号