化工学报 ›› 2020, Vol. 71 ›› Issue (1): 388-396.DOI: 10.11949/0438-1157.20191317

李莹莹1,2( ),邓谦谦1,2,刘浩1,2,刘其春1,2,顾正桂2,王昉1(

),邓谦谦1,2,刘浩1,2,刘其春1,2,顾正桂2,王昉1( )

)

收稿日期:2019-11-04

修回日期:2019-11-18

出版日期:2020-01-05

发布日期:2020-01-05

通讯作者:

王昉

作者简介:李莹莹(1994—),女,硕士研究生,基金资助:

Yingying LI1,2( ),Qianqian DENG1,2,Hao LIU1,2,Qichun LIU1,2,Zhenggui GU2,Fang WANG1(

),Qianqian DENG1,2,Hao LIU1,2,Qichun LIU1,2,Zhenggui GU2,Fang WANG1( )

)

Received:2019-11-04

Revised:2019-11-18

Online:2020-01-05

Published:2020-01-05

Contact:

Fang WANG

摘要:

基于丝素的高分子复合材料可以广泛地应用于组织工程、生物医药和半导体材料等领域。通过物理-共混技术制备了一种新型生物高分子丝素/聚乳酸复合膜。利用扫描电镜、傅里叶红外光谱、拉曼光谱、X射线衍射和热分析技术对其形貌、结构和相态组分以及热稳定性进行了表征,探究了不同比例复合膜的微结构、相互作用机理和热稳定性。结果表明:随着丝素含量的增加,复合膜中的β-折叠含量增多,α-螺旋和无规卷曲含量减少,玻璃化转变温度提高;由于丝素与聚乳酸间的相互作用,提高了复合膜的热稳定性。

中图分类号:

李莹莹, 邓谦谦, 刘浩, 刘其春, 顾正桂, 王昉. 新型丝素复合膜的微结构表征及热稳定性[J]. 化工学报, 2020, 71(1): 388-396.

Yingying LI, Qianqian DENG, Hao LIU, Qichun LIU, Zhenggui GU, Fang WANG. Microstructure characterization and thermal stability of new silk fibroin composite films[J]. CIESC Journal, 2020, 71(1): 388-396.

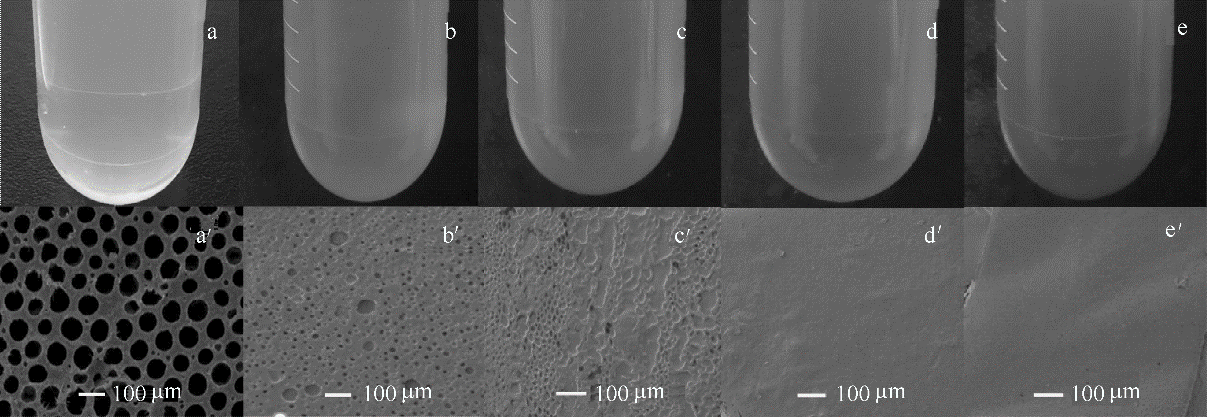

图1 不同质量比例制备的MSF/PLA复合膜的电镜图(上层图a~e分别表示丝素蛋白/聚乳酸混合溶液,MSF/PLA-0∶5,MSF/PLA-1∶5,MSF/PLA-5∶5, MSF/PLA-5∶1和MSF/PLA-5∶0;下层图a'~e'分别是对应比例丝素聚乳酸复合膜电镜图)

Fig.1 SEM of MSF/PLA composite film prepared with different mass ratios(The upper layer a—e are silk fibroin/polylactic acid mixed solution, MSF/PLA-0∶5, MSF/PLA-1∶5, MSF/PLA-5∶5, MSF/PLA-5∶1 and MSF/PLA-5∶0, respectively; The lower layer a'—e' are SEM images corresponding to the ratio of the silk fibroin and polylactic acid composite films, respectively)

| Sample | β-sheet/% | α-helix & random coils /% | Turns/% | Side chains/% |

|---|---|---|---|---|

| MSF/PLA-1∶5 | 12.23 | 73.89 | 12.56 | 1.32 |

| MSF/PLA-5∶5 | 15.54 | 71.03 | 10.79 | 2.64 |

| MSF/PLA-5∶1 | 18.24 | 68.99 | 9.56 | 3.21 |

| MSF/PLA-5∶0 | 23.29 | 66.80 | 8.55 | 1.36 |

表1 复合材料中桑蚕丝素蛋白各组分含量

Table 1 Contents of silk fibroin protein in composite materials

| Sample | β-sheet/% | α-helix & random coils /% | Turns/% | Side chains/% |

|---|---|---|---|---|

| MSF/PLA-1∶5 | 12.23 | 73.89 | 12.56 | 1.32 |

| MSF/PLA-5∶5 | 15.54 | 71.03 | 10.79 | 2.64 |

| MSF/PLA-5∶1 | 18.24 | 68.99 | 9.56 | 3.21 |

| MSF/PLA-5∶0 | 23.29 | 66.80 | 8.55 | 1.36 |

| Item | MSF/PLA-0∶5 | MSF/PLA-1∶5 | MSF/PLA-5∶5 | MSF/PLA-5∶1 | MSF/PLA-5∶0 |

|---|---|---|---|---|---|

| Tg/℃ | 55.81 | 58.68 | 65.02 | 74.33 | 154.32 |

| Tm /℃ | 150.29 | 150.01 | 147.11 | 144.98 | — |

| ΔHm/(J·g-1) | 30.23 | 25.37 | 18.68 | 14.57 | — |

| ΔCp/(J·g-1·℃-1) | 0.39 | 0.40 | 0.43 | 0.46 | — |

| XC-DSC | 0.33 | 0.27 | 0.19 | 0.11 | — |

| XMAP-DSC | 0.63 | 0.66 | 0.70 | 0.75 | — |

| XRAP-DSC | 0.04 | 0.07 | 0.11 | 0.14 | — |

| XC-XRD | 0.35 | 0.30 | 0.21 | 0.12 | — |

| XMAP-XRD | 0.59 | 0.63 | 0.69 | 0.74 | — |

| XRAP-XRD | 0.06 | 0.07 | 0.10 | 0.14 | — |

| Tonset /℃ | 346.27 | 330.19 | 305.38 | 283.37 | 272.76 |

| Tp/℃ | 350.69 | 336.95 | 316.06 | 289.62 | 280.27 |

| ΔYw /% | 0.42 | 1.73 | 4.80 | 6.07 | 6.99 |

表2 复合膜的热力学参数、相态的相对含量以及TG数据

Table 2 Thermodynamic parameters, phase component content and TG data of composite film

| Item | MSF/PLA-0∶5 | MSF/PLA-1∶5 | MSF/PLA-5∶5 | MSF/PLA-5∶1 | MSF/PLA-5∶0 |

|---|---|---|---|---|---|

| Tg/℃ | 55.81 | 58.68 | 65.02 | 74.33 | 154.32 |

| Tm /℃ | 150.29 | 150.01 | 147.11 | 144.98 | — |

| ΔHm/(J·g-1) | 30.23 | 25.37 | 18.68 | 14.57 | — |

| ΔCp/(J·g-1·℃-1) | 0.39 | 0.40 | 0.43 | 0.46 | — |

| XC-DSC | 0.33 | 0.27 | 0.19 | 0.11 | — |

| XMAP-DSC | 0.63 | 0.66 | 0.70 | 0.75 | — |

| XRAP-DSC | 0.04 | 0.07 | 0.11 | 0.14 | — |

| XC-XRD | 0.35 | 0.30 | 0.21 | 0.12 | — |

| XMAP-XRD | 0.59 | 0.63 | 0.69 | 0.74 | — |

| XRAP-XRD | 0.06 | 0.07 | 0.10 | 0.14 | — |

| Tonset /℃ | 346.27 | 330.19 | 305.38 | 283.37 | 272.76 |

| Tp/℃ | 350.69 | 336.95 | 316.06 | 289.62 | 280.27 |

| ΔYw /% | 0.42 | 1.73 | 4.80 | 6.07 | 6.99 |

| 1 | Yu S, Yang W, Chen S, et al. Floxuridine-loaded silk fibroin nanospheres[J]. RSC Advances, 2014, 4(35): 18171. |

| 2 | Mitropoulos A N, Marelli B, Ghezzi C E, et al. Transparent, nanostructured silk fibroin hydrogels with tunable mechanical properties[J]. ACS Biomater. Sci. Eng., 2015, 1(10): 964-970. |

| 3 | Koh L D, Cheng Y, Teng C P, et al. Structures, mechanical properties and applications of silk fibroin materials[J]. Prog. Polym. Sci., 2015, 46: 86-110. |

| 4 | 李莹莹, 王昉, 刘其春, 等. 丝素蛋白及其复合材料的研究进展[J]. 材料工程, 2018, 46 (8): 18-30. |

| Li Y Y, Wang F, Liu Q C, et al. Research progress of silk fibroin and its composites[J] . Materials Engineering, 2018, 46 (8): 18-30. | |

| 5 | Pritchard E M, Dennis P B, Omenetto F, et al. Physical and chemical aspects of stabilization of compounds in silk [J]. Biopolymers, 2012, 97(6): 479-498. |

| 6 | Zhu H L, Feng X X, Zhang H P, et al. Structural characteristics and properties of silk fibroin/poly (lactic acid) blend films[J]. Biomater. Sci. Polym. Ed., 2009, 20 (9): 1259-1274. |

| 7 | 王利君, 熊杰, 骆菁菁, 等. 聚乳酸-聚己内酯/丝素蛋白三元复合纳米纤维膜支架的结构与性能[J]. 纺织学报, 2017, 38(5): 8-13. |

| Wang L J, Xiong J, Luo J J, et al. Structure and properties of polylactic acid-polycaprolactone/ silk fibroin composite nanofibrous scaffolds [J]. J. Text. Res., 2017, 38(5): 8-13. | |

| 8 | 肖红伟, 熊杰, 李妮, 等. 聚乳酸-乙醇酸共聚物/丝素共混纳米纤维多孔膜的制备及性能[J]. 高分子材料科学与工程, 2011, 27(12): 142-145. |

| Xiao H W, Xiong J, Li N, et al. Preparation and properties of poly(lactide-co-glycolide)/silk blend nanofibrous porous membrane[J]. Polymer Materials Science & Engineering, 2011, 27(12): 142-145. | |

| 9 | Zhang C, Zhang Y P, Shao H L, et al. Hybrid silk fibers dry-spun from regenerated silk fibroin/ graphene oxide aqueous solutions[J]. ACS Appl. Mater. Interfaces, 2016, 8: 3349-3358. |

| 10 | Suzuki S, Dawson R A, Chirila T V, et al. Treatment of silk fibroin with poly(ethylene glycol) for the enhancement of corneal epithelial cell growth[J]. Journal of Functional Biomaterials, 2015, 6(2): 345-366. |

| 11 | Martin O, Averous L. Poly(lactic acid): plastication and properties of biodegradable multiphase systems[J]. Polymer, 2001, 42(14): 6209-6219. |

| 12 | Xiao H, Yang L, Ren X, et al. Kinetics and crystal structure of poly(lactic acid) crystallized nonisothermally: effect of plasticizer and nucleating agent[J]. Polymer Composites, 2010, 31(12): 2057-2068. |

| 13 | Shao J, Guo Y, Xiang S, et al. The morphology and spherulite growth of PLA stereocomplex in linear and branched PLLA/PDLA blends: effects of molecular weight and structure[J]. Crystengcomm, 2015, 18(2): 274-282. |

| 14 | 倪莉, 王璋, 姚文华, 等. 丝素蛋白结构的研究(1): 探讨氯化钙溶液溶解丝素的机理[J]. 中国食品学报, 2001, 1(1): 12-18. |

| Ni L, Wang Z, Yao W H, et al. Study on the structure of silk fibroin protein(1): The mechanism of dissolving fibroin in calcium chloride solution [J]. Journal of Chinese Food, 2001, 1(1): 12-18. | |

| 15 | Lai S M, Hsieh Y T. Preparation and properties of polylactic acid (PLA)/silica nanocomposites[J]. J. Macromol. Sci. B, 2016, 55(3): 211-228. |

| 16 | Zhou S B, Zheng X T, Yu X J, et al. Hydrogen bonding interaction of poly(D, L-lactide)/hydroxyapatite nanocomposites[J]. Chem. Mater., 2007, 19: 247-253. |

| 17 | Zhong J, Ma M, Li W, et al. Self-assembly of regenerated silk fibroin from random coil nanostructures to antiparallel β-sheet nanostructures[J]. Biopolymers, 2015, 101(12): 1181-1192. |

| 18 | 于海洋, 王昉, 刘其春, 等.新型丝素蛋白膜的结构和热分解动力学机理[J].物理化学学报, 2017, 33(2): 344-355. |

| Yu H Y, Wang F, Liu Q C, et al. Structure and kinetics of thermal decomposition mechanism of novel silk fibroin films[J].Acta Physico-Chimica Sinica, 2017, 33(2): 344-355. | |

| 19 | Hu X, Kaplan D, Cebe P. Determining beta-sheet crystallinity in fibrous proteins by thermal analysis and infrared spectroscopy[J]. Macromolecules, 2006, 39: 6161-6170. |

| 20 | Wang F, Wu H, Venkataraman V, et al. Silk fibroin-poly(lactic acid) biocomposites: effect of protein-synthetic polymer interactions and miscibility on material properties and biological responses [J]. Materials Science & Engineering C, 2019, 104: 109890. |

| 21 | Wool R P, Bretzlaff R S, Li B Y, et al. Infrared and Raman spectroscopy of stressed polyethylene[J]. Journal of Polymer Science, Part B (Polymer Physics), 1986, 24(5): 1039-1066. |

| 22 | Xu Y, Liang L. Surface-enhanced resonance Raman scattering of phycoerythrin adsorbed by silver hydrosols[J]. Applied Spectroscopy, 1994, 48(9): 1147-1149. |

| 23 | Carey P R. Biochemical Applications of Raman and Resonance Raman Spectroscopies[M]. New York: Academic Press, 1982: 71-96. |

| 24 | Bandekar J, Krimm S. Vibrational analysis of peptides, polypeptides, and proteins: characteristic amide bands of β-turns[J]. Proc. Natl. Acad. Sci. USA, 1979, 76(2): 774-777. |

| 25 | Kister G, Cassanas G, Vert M, et al. Vibrational analysis of poly(L-lactic acid)[J]. Journal of Raman Spectroscopy, 2010, 26(4): 307-311. |

| 26 | Furukawa T, Sato H, Murakami R, et al. Raman microspectroscopy study of structure, dispersibility, and crystallinity of poly(hydroxybutyrate)/poly(L-lactic acid) blends[J]. Polymer, 2006, 47(9): 3132-3140. |

| 27 | Huang S M, Hwang J J, Liu H J, et al. Crystallization behavior of poly(L-lactic acid)/montmorillonite nanocomposites[J]. J. Appl. Polym. Sci., 2010, 117(1): 434-442. |

| 28 |

Bruckmoser K, Resch K. Effect of processing conditions on crystallization behavior and mechanical properties of poly(lactic acid) staple fibers[J]. J. Appl. Polym. Sci., 2015, 132(33). doi: 10.1002/app.42432.

DOI |

| 29 | Pluta M. Morphology and properties of polylactide modified by thermal treatment, filling with layered silicates and plasticization[J]. Polymer, 2004, 45(24): 8239-8251. |

| 30 | Wu T M, Wu C Y. Biodegradable poly (lactic acid)/chitosan-modified montmorillonite nanocomposites: preparation and characterization[J]. Polymer Degradation & Stability, 2006, 91(9): 2198-2204. |

| 31 | Zhang J, Yan D X, Xu J Z, et al. Highly crystallized poly (lactic acid) under high pressure[J]. AIP Advances, 2012, 2(4): 042159. |

| 32 | Pal A, Katiyar V. Melt processing of biodegradable poly (lactic acid)/ functionalized chitosan nanocomposite films: mechanical modeling with improved oxygen barrier and thermal properties[J]. J. Polym. Res., 2017, 24 (10): 173. |

| 33 | Iannace S, Maffezzoli A, Leo G, et al. Influence of crystal and amorphous phase morphology on hydrolytic degradation of PLLA subjected to different processing conditions[J]. Polymer, 2001, (42): 3799-3807. |

| 34 | Wang F, Wolf N, Rocks E M, et al. Comparative studies of regenerated water-based Mori, Thai, Eri, Muga and Tussah silk fibroin films[J]. J. Therm. Anal. Calorim., 2015, 122(3): 1069-1076. |

| 35 | Gaur U. Advanced thermal analysis system (ATHAS) polymer heat capacity data bank[C]//ACS Symposium. 1982: 355-366. |

| 36 | Sheng S J, Hu X, Wang F, et al. Mechanical and thermal property characterization of poly-L-lactide(PLLA) scaffold developed using pressure-controllable green foaming technology[J]. Materials Science and Engineering: C, 2015, 49: 612-622. |

| 37 | 刘其春, 王昉, 李莹莹, 等. 比较两种丝素膜的结构、热分解机理与热力学参数[J]. 中国科学: 化学, 2019, (7): 1014-1029. |

| Liu Q C, Wang F, Li Y Y, et al. Comparative studies of structure, thermal decomposition mechanism and thermodynamic parameters of two kinds of silk fibroin films [J]. Chinese Science: Chemistry, 2019, (7): 1014-1029. |

| [1] | 苏伟, 马东旭, 金旭, 刘忠彦, 张小松. 表面润湿性对霜层传递特性影响可视化实验研究[J]. 化工学报, 2023, 74(S1): 122-131. |

| [2] | 于宏鑫, 邵双全. 水结晶过程的分子动力学模拟分析[J]. 化工学报, 2023, 74(S1): 250-258. |

| [3] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [4] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [5] | 傅予, 刘兴翀, 王瀚雨, 李海敏, 倪亚飞, 邹文静, 雷月, 彭永姗. F3EACl修饰层对钙钛矿太阳能电池性能提升的研究[J]. 化工学报, 2023, 74(8): 3554-3563. |

| [6] | 胡兴枝, 张皓焱, 庄境坤, 范雨晴, 张开银, 向军. 嵌有超小CeO2纳米粒子的碳纳米纤维的制备及其吸波性能[J]. 化工学报, 2023, 74(8): 3584-3596. |

| [7] | 张澳, 罗英武. 低模量、高弹性、高剥离强度丙烯酸酯压敏胶[J]. 化工学报, 2023, 74(7): 3079-3092. |

| [8] | 王杰, 丘晓琳, 赵烨, 刘鑫洋, 韩忠强, 许雍, 蒋文瀚. 聚电解质静电沉积改性PHBV抗氧化膜的制备与性能研究[J]. 化工学报, 2023, 74(7): 3068-3078. |

| [9] | 蔡斌, 张效林, 罗倩, 党江涛, 左栗源, 刘欣梅. 导电薄膜材料的研究进展[J]. 化工学报, 2023, 74(6): 2308-2321. |

| [10] | 崔张宁, 胡紫璇, 吴雷, 周军, 叶干, 刘田田, 张秋利, 宋永辉. 可降解纤维素基材料的耐水性能研究进展[J]. 化工学报, 2023, 74(6): 2296-2307. |

| [11] | 李振, 张博, 王丽伟. PEG-EG固-固相变材料的制备和性能研究[J]. 化工学报, 2023, 74(6): 2680-2688. |

| [12] | 陈韶云, 徐东, 陈龙, 张禹, 张远方, 尤庆亮, 胡成龙, 陈建. 单层聚苯胺微球阵列结构的制备及其吸附性能[J]. 化工学报, 2023, 74(5): 2228-2238. |

| [13] | 代佳琳, 毕唯东, 雍玉梅, 陈文强, 莫晗旸, 孙兵, 杨超. 热物性对混合型CPCMs固液相变特性影响模拟研究[J]. 化工学报, 2023, 74(5): 1914-1927. |

| [14] | 葛运通, 王玮, 李楷, 肖帆, 于志鹏, 宫敬. 多相分散体系中微油滴与改性二氧化硅表面间作用力的AFM研究[J]. 化工学报, 2023, 74(4): 1651-1659. |

| [15] | 苏晓丹, 朱干宇, 李会泉, 郑光明, 孟子衡, 李防, 杨云瑞, 习本军, 崔玉. 湿法磷酸半水工艺考察与石膏结晶过程研究[J]. 化工学报, 2023, 74(4): 1805-1817. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号